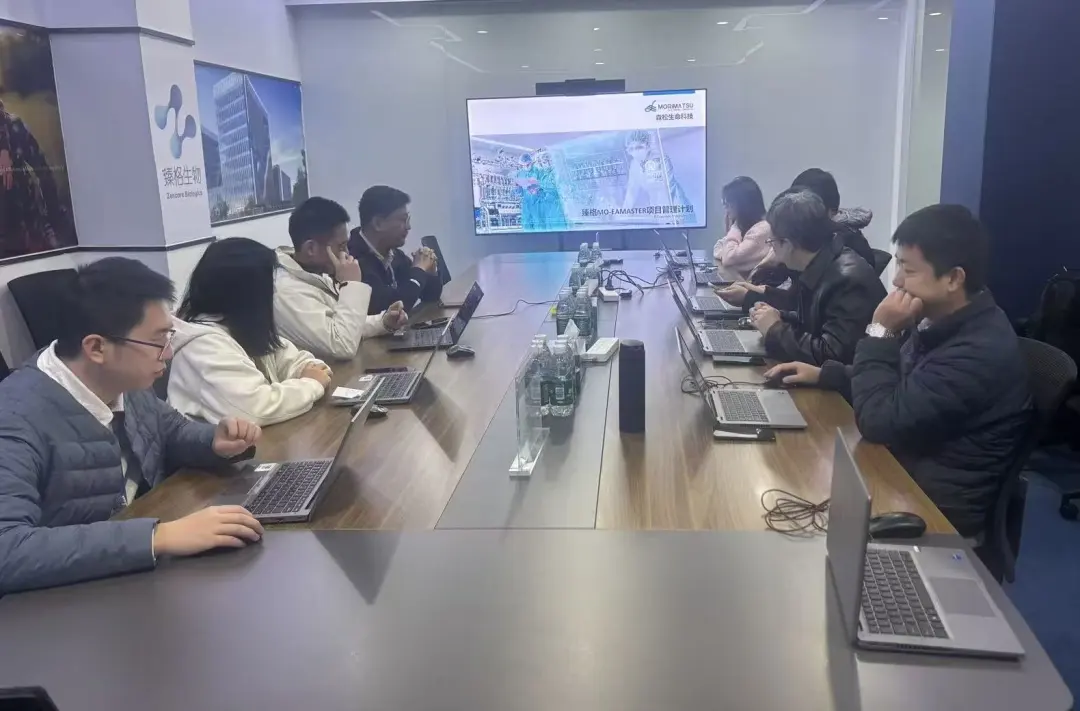

On January 9, 2026, Morimatsu LifeSciences and Zencore Biologics successfully held the Mo-EAMaster Phase II Project Kickoff Meeting. Building on the strong results of Phase I, the two companies are once again collaborating to drive the next stage of digital intelligence upgrades in pharmaceutical asset management.

Phase I Collaboration Lays Solid Foundation with Remarkable Results

In their initial collaboration, Morimatsu applied its proven Mo-EAMaster solution to help Zencore Biologics achieve end-to-end digitalization of equipment management:

· Equipment records were fully digitized, and maintenance processes were standardized, eliminating long-standing challenges caused by fragmented and siloed information;

· A seamless flow of online data was established across the entire equipment lifecycle—from installation and operation to maintenance and decommissioning—bringing all information into a centralized, unified data platform;

· Equipment Overall Equipment Effectiveness (OEE) improved significantly, while a strong compliance framework was put in place, creating a solid foundation for deeper and more advanced collaboration in Phase II.

02 Core Support: Morimatsu EAM - Powering Digital Equipment Management

· Compliance First: Fully aligned with ISO 55000 standards and GMP requirements, ensuring comprehensive compliance across the entire equipment lifecycle;

· Full Lifecycle Coverage: Delivers closed-loop control of equipment from acceptance and installation through operation, maintenance, and decommissioning;

· Efficient Collaboration: Enables cross-platform access via web, mobile, and H5, with intuitive equipment dashboards and data visualization. Core functions including maintenance, calibration, and spare parts management are fully integrated to support refined management and streamlined operations.

03 Phase II Collaboration Targets Four Key Modules for Focused Optimization

The Phase II project addresses operational pain points through feature enhancements and user experience optimization, upgrading four core modules to deliver more precise, data-driven control across the equipment lifecycle.

· Maintenance Module: New capabilities are aligned with real-world operational needs, improving fault resolution and work order management. Combined with an integrated maintenance knowledge base, the module increases efficiency and reduces unplanned downtime.

· Calibration Module: Adds dynamic adjustment capabilities while standardizing calibration records and task assignment, ensuring full traceability and strong alignment with GMP requirements.

· Maintenance Module: Strengthens planning and execution workflows, enhances reminder and alert mechanisms, and improves cross-platform coordination to support timely, standardized responses.

· Inspection Module: Digitizes inspection data that was previously managed offline, enabling centralized storage, traceability, and audit readiness while improving overall process efficiency.

04 Full-Cycle Management: Closed-Loop Collaboration for Project Success

With clearly defined milestones—including requirements analysis, functional development, CSV validation, and final acceptance—Morimatsu and Zencore Biologics have established well-defined roles and responsibilities. Through multiple communication channels, the teams ensure close coordination, rapid execution, and proactive risk identification, maintaining steady and disciplined project delivery.

Looking ahead, Morimatsu LifeSciences and Zencore Biologics will treat the Phase II project as a new starting point for deeper collaborative innovation. By leveraging the technical strengths and broad application scenarios of the Mo-EAMaster system, they will convert digital management capabilities into measurable business outcomes—strengthening compliance, improving operational efficiency, and advancing intelligent asset management across the pharmaceutical industry. Together, they are poised to open a new chapter of mutually beneficial partnership.

About Zencore Biologics

Shanghai Zencore Bio-Tech Company (hereafter referred to as "Zencore Biologics") provides a full range of CDMO services from pre-clinical development to commercialized production, with the core businesses covering macromolecular biopharmaceuticals CDMO, antibody-drug conjugates (ADC) CDMO, catalog medium, medium customized development and production services, analysis and testing services, quality and registration services, etc. to help and boost the R&D and industrialization progress of macromolecular biopharmaceuticals in global pharmaceutical companies and scientific research institutions.

Zencore Biologics has been always upholding such values of "Hold on to the Core and Carry on the Responsibility for Ultimate Perfection", aiming to better provide global partners with high-quality and efficient CDMO services, empower clients to rapidly transform products from concept to commercialized production, integrate best processes, and make good medicines that everyone can afford.

About Morimatsu LifeSciences

Morimatsu LifeSciences is a key business segment of Morimatsu International Holdings Limited (Stock Code: 2155.HK). It comprises Shanghai Morimatsu Pharmaceutical Equipment Engineering Co., Ltd., Morimatsu (Suzhou) LifeSciences Co., Ltd., Shanghai Morimatsu Biotechnology Co., Ltd., Shanghai Mori-Biounion Technology Co., Ltd., Shanghai Morisora Technology Co., Ltd., Bioengineering AG, Pharmadule Morimatsu AB, and its affiliated companies.

Morimatsu LifeSciences is dedicated in providing core equipment, process systems, and smart modular facility solutions, and services for the pharmaceutical, biopharmaceutical, medical aesthetics, and fast-moving consumer goods (FMCG) sectors including (cosmetics, food, and health supplements), as well as data centers.

Our team comprises highly experienced professionals with deep expertise in process R&D, engineering design, advanced manufacturing, compliance and validation consulting, production execution, and intelligent operations. With broad experience across diverse industries, we fully understand the unique characteristics and process requirements of various products. This enables us to deliver tailored, end-to-end process solutions from the conceptual design stage, precisely aligned with client’s specific needs.

Morimatsu LifeSciences has established a strong global presence, supported by advanced R&D centers, design hubs, and state-of-the-art manufacturing facilities worldwide. Our well-established service network spans Europe,USA,Asia-Pacific, and emerging markets. We have successfully delivered outstanding, customized solutions to clients in over 40 countries and regions, gaining extensive experience in international project execution.

As a multinational enterprise with core strengths in process technology, modular facility construction, and intelligent manufacturing, Morimatsu LifeSciences is dedicated to meeting the evolving equipment and system needs of our key industries. Through continuous innovation and technological advancement, we are steadily expanding our global footprint, driving our international strategy forward, and delivering Morimatsu’s expertise, reliability, and innovation to the global life sciences and related sectors.