In the world of biopharmaceutical manufacturing, Chinese Hamster Ovary (CHO) cells are the workhorses behind modern antibody drugs—producing nearly 90% of the world’s supply. As demand continues to grow, manufacturers face a familiar challenge: how to scale up high-density cell cultures while maintaining strong productivity and cell health. At the heart of this challenge is a delicate balance. On one hand, cells need efficient mass transfer to receive enough oxygen and nutrients. On the other, excessive shear stress can damage cells, reduce viability, and hurt overall performance.

This is where impeller design makes a critical difference. Impeller blades shape the flow patterns inside the bioreactor, directly influencing both mixing efficiency and shear levels. At Morimatsu, impeller development is guided by science and data. The company has systematically evaluated how different blade designs perform in high-density CHO cultures.

Understanding the“Temperament”of Cells:

Cell Characteristics in High-Density Cultures

Highly Sensitive to Shear Stress

CHO cells do not have a protective cell wall, which makes them especially vulnerable to mechanical stress. Excessive shear forces can damage the cell membrane and lead to cell death. Even lower, non-lethal levels of shear can slow cell growth and reduce the efficiency of drug production.

Oxygen Demand Surges at High Cell Densities

In high-density cultures, cell concentrations can reach hundreds of millions per milliliter, driving oxygen demand sharply upward. To keep cells healthy and productive, oxygen must be delivered efficiently and evenly throughout the bioreactor. Even small low-oxygen zones can disrupt cellular metabolism and hurt performance.

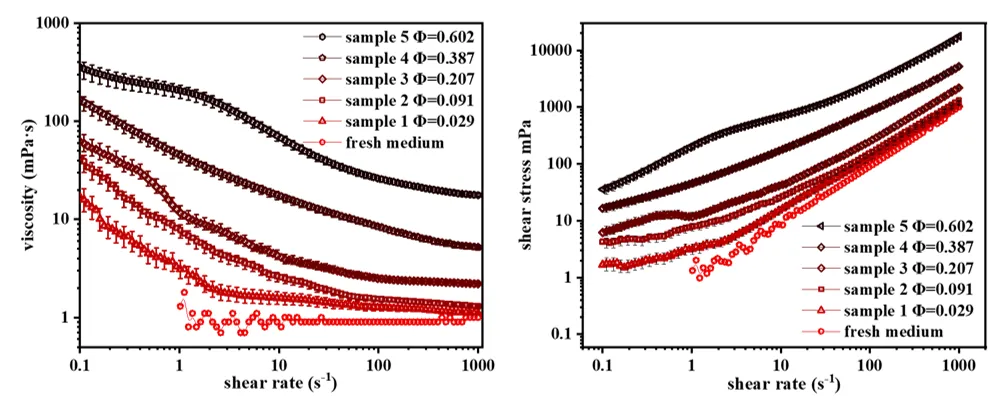

Adding to the challenge, high-density cell suspensions don’t behave like ordinary fluids. Their viscosity changes with movement: the culture is thick when still, but becomes thinner as it’s mixed. This “shear-thinning” behavior significantly affects how fluids move inside the reactor and pushes the limits of traditional bioreactor design models.

Figure 1. Rheological behavior of cell suspensions at different volume fractions

Finding the “Right Match” for Cells:

Performance Comparison of Five Axial-Flow Impeller Designs

Morimatsu uses advanced computational fluid dynamics (CFD) simulations to evaluate the performance of five widely used axial-flow impeller designs under the same operating conditions. The designs tested include the three-narrow-blade hydrofoil, pitched-blade, three-wide-blade hydrofoil, split-blade, and elephant-ear impellers.

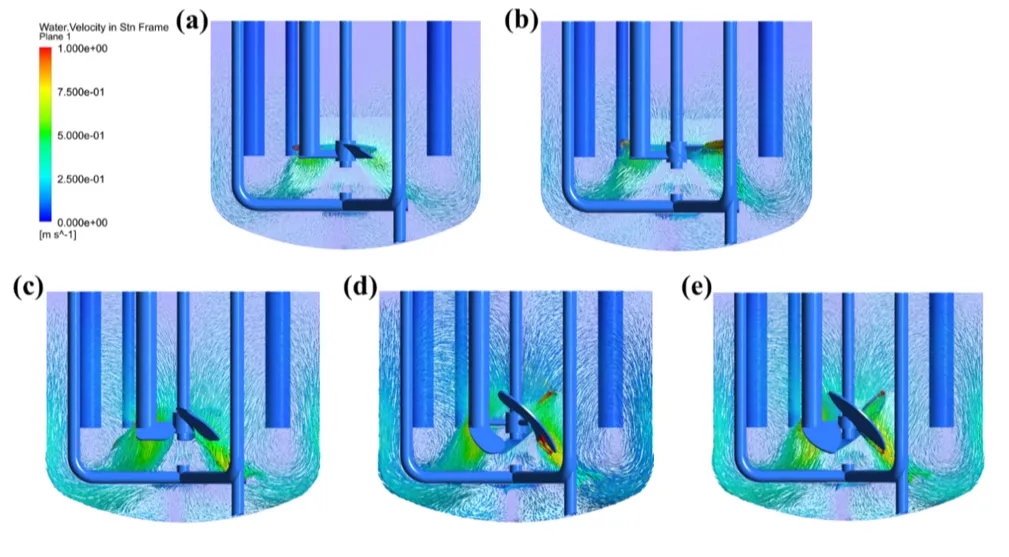

Flow and Circulation

01 Which Impeller Keeps the Whole System Moving?

Fluid circulation in a bioreactor is like a city’s transportation network—it needs strong, consistent flow to prevent stagnant “dead zones” where mass transfer breaks down. Simulation results show that wide-blade impellers perform better at driving full-scale circulation.

Figure 2. Velocity contours and flow vectors for different impeller designs

Narrow-blade impellers mainly move fluid in the lower and middle regions of the reactor, leaving very little motion near the surface. This can easily lead to dead zones. In contrast, wide-blade designs, such as elephant-ear impellers, generate stronger axial pumping and create uniform circulation throughout the vessel, ensuring that all cells remain well mixed and supplied.

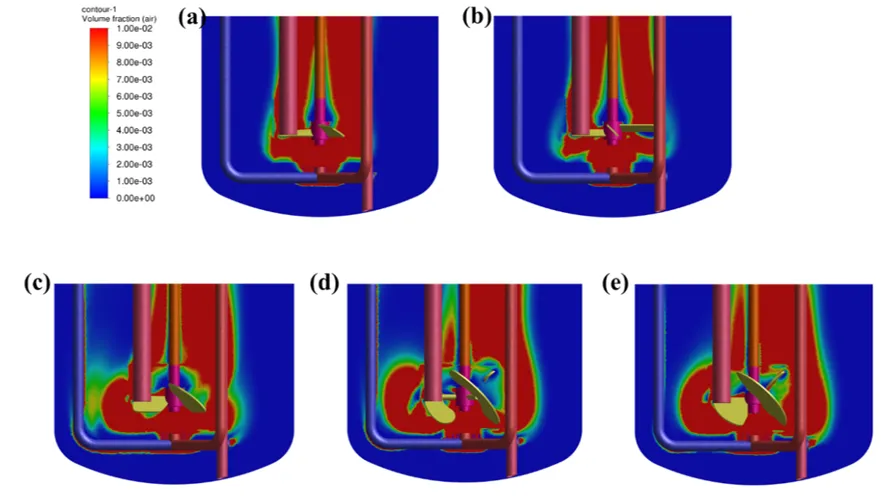

Gas Dispersion

02 Which Impeller Handles Bubbles Best?

Cell respiration depends on a steady oxygen supply delivered through gas bubbles. How well those bubbles are dispersed throughout the reactor directly affects dissolved oxygen levels and, ultimately, cell growth and productivity.

Figure 3. Gas holdup distribution for different impeller designs

Wide-blade impellers, with their larger surface area and stronger circulation, provide more effective gas dispersion than other designs. The elephant-ear impeller performs especially well by capturing and redistributing bubbles within the impeller zone. This prevents bubbles from rising too quickly along the vessel wall and improves oxygen utilization, creating a more uniform dissolved oxygen environment for the cells.

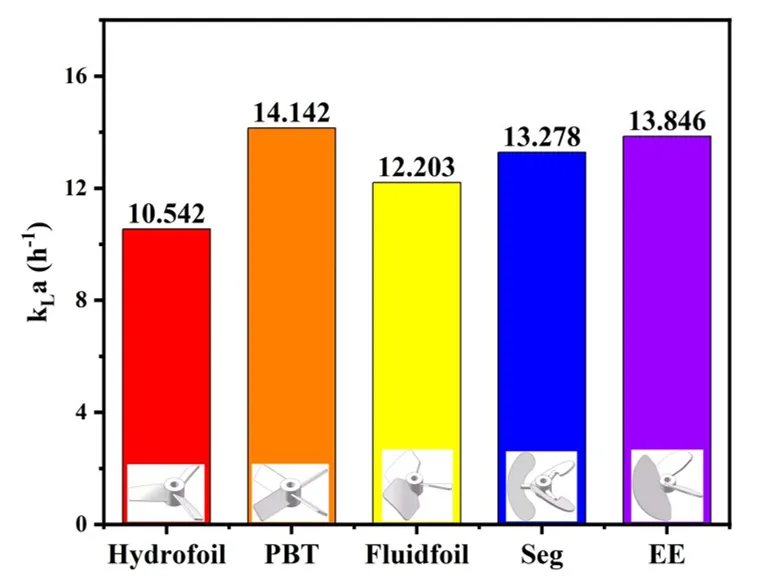

Mass Transfer Efficiency

03 Which Impeller Delivers the Most Consistent Oxygen Supply?

Mass transfer efficiency is commonly measured by the volumetric oxygen transfer coefficient, or kLa, which reflects how effectively oxygen moves from gas bubbles into the liquid. The results show that pitched-blade and elephant-ear impellers achieve the highest kLa values.

Figure 4. Volumetric oxygen transfer coefficients for different impeller designs

What sets the elephant-ear impeller apart is not just its high kLa, but its ability to deliver oxygen evenly throughout the reactor. Its strong and uniform gas dispersion helps maintain stable dissolved oxygen levels as cells circulate, minimizing fluctuations and creating a more consistent environment for CHO cell growth and productivity.

Shear Control

04 Which Impeller Is the Most Cell-Friendly?

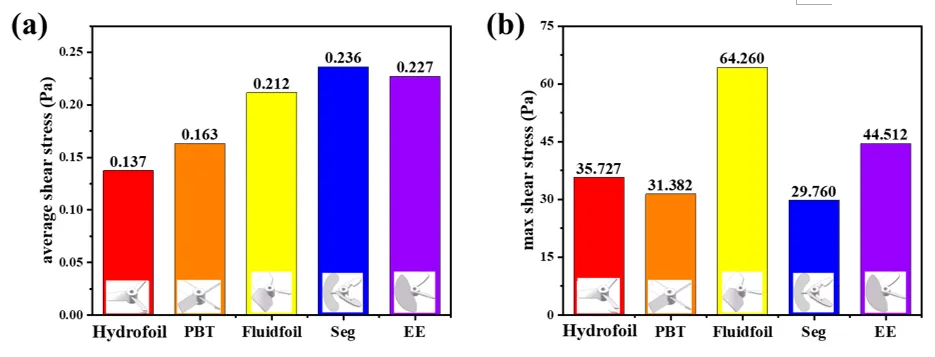

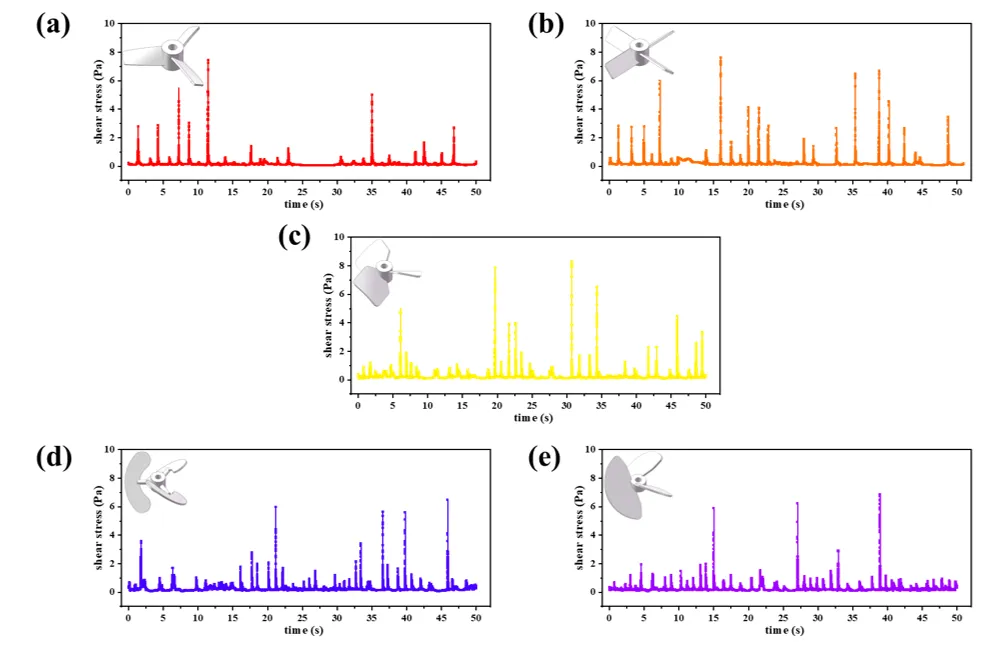

Managing shear stress is the final—and most critical—challenge. All impellers generate their highest shear forces at the blade tips, where levels can exceed what cells can tolerate. Fortunately, these high-risk zones are small. What really matters is how often and how long cells are exposed to damaging shear as they circulate through the bioreactor. By tracking individual cell paths, simulations show that elephant-ear impellers expose cells to high shear levels (>2 Pa, a sub-lethal range) less frequently and for shorter periods than other designs.

Figure 5. (a) Volume-averaged and (b) maximum shear stress for different impeller designs

Figure 6. Shear stress over time experienced by CHO cells with different impellers

These results indicate that elephant-ear impellers create a gentler, more stable mechanical environment, reducing the risk of cumulative stress damage. This makes them especially well-suited for shear-sensitive CHO cell cultures.

Conclusion

Across all four performance dimensions, the elephant-ear impeller delivers the best balance between efficient mass transfer and gentle shear control. Its wide, curved blade design provides two key advantages:

1.It promotes strong circulation and uniform gas dispersion, ensuring consistent delivery of oxygen and nutrients.

2.It creates a stable flow environment that reduces mechanical stress on sensitive cells.

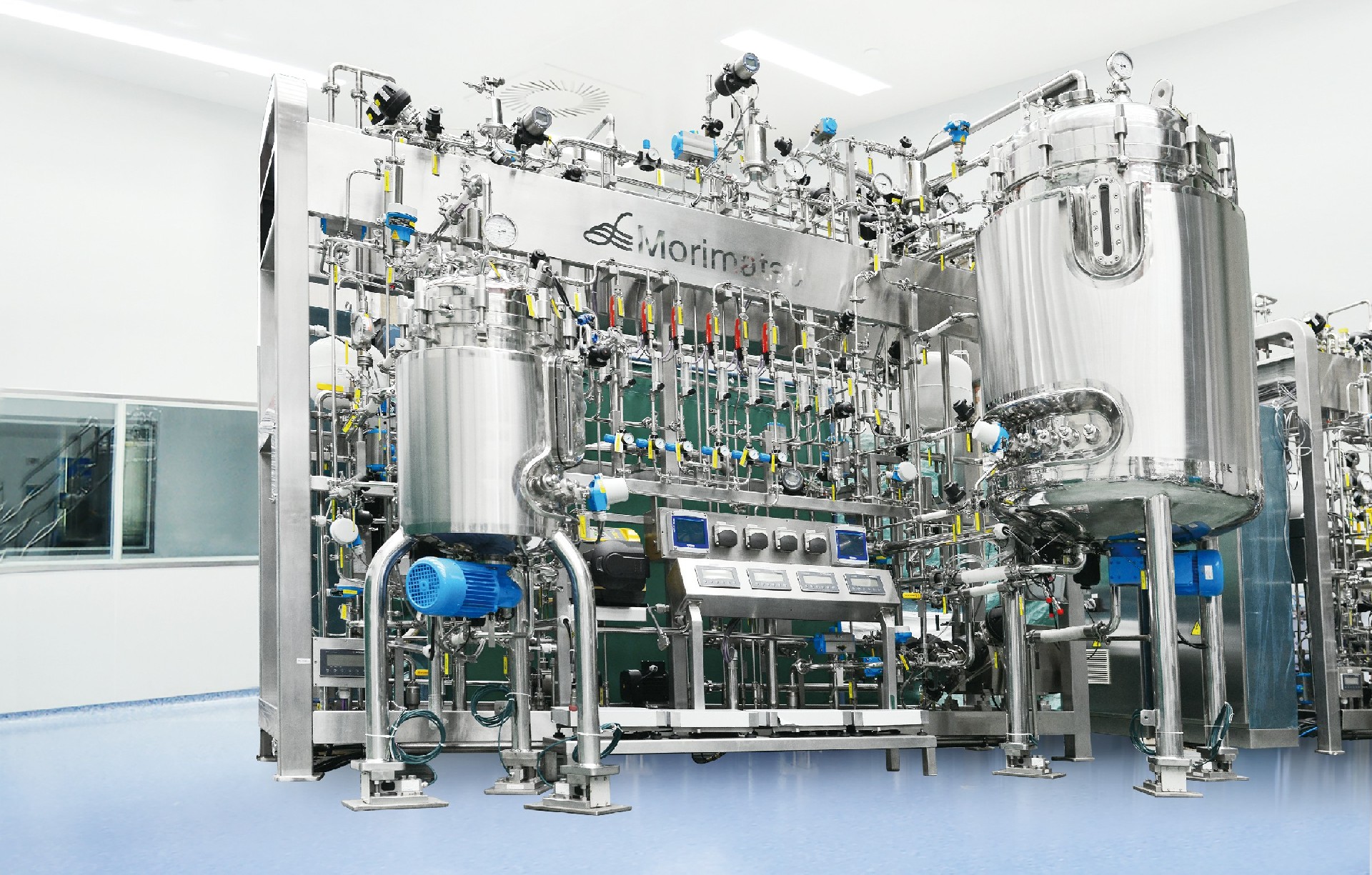

This is why Morimatsu Glass Bioreactors use the elephant-ear impeller as a core technology. By applying scientific, data-driven design, Morimatsu aligns equipment performance with the real needs of cells—supporting reliable, large-scale success in high-density cell culture processes.

Glass Bioreactor Stainless Steel Bioreactor System

As the biopharmaceutical industry pushes for higher efficiency, success increasingly depends on the combination of strong scientific insight and advanced engineering. Morimatsu has shifted from traditional, experience-based design to a data- and model-driven approach, using tools like CFD simulations to precisely optimize impeller performance. Looking ahead, the integration of AI and machine learning will make bioreactor design even smarter and more precise. Morimatsu remains committed to advancing this field—delivering high-performance, science-driven equipment that helps pharmaceutical companies overcome capacity limits, improve production efficiency, and bring more high-quality biologics to patients worldwide.

References

[1] Botao Zhang, Xinran Zhang, Qingyuan Ran, Weijian Zhang, Gance Dai, Liang Zhao, Qian Ye, Wen-Song Tan. Rheology of CHO Cell Suspensions and Its Effects on High‐Density Cultivation Process and Bioreactor Design [J]. Biotechnology Journal. 2025, 20(3): e70003.

[2] Botao Zhang, Qingyuan Ran, Gance Dai, Qian Ye, Liang Zhao, Wen-Song Tan. Comparison of Perfusion Culture Performance in Orbitally Shaken Bioreactors and Stirred Tank Bioreactors: A Spatiotemporal Dynamic Analysis of Shear Stress and Mass Transfer Based on Suspension Rheology [J]. Processes. 2025, 13(4): 955.

[3] Walsh G, Walsh E. Biopharmaceutical benchmarks 2022[J]. Nature Biotechnology, 2022, 40(12): 1722-1760.

[4] Neunstoecklin B, Stettler M, Solacroup T, et al. Determination of the maximum operating range of hydrodynamic stress in mammalian cell culture[J]. Journal of Biotechnology, 2015, 194: 100-109.

[5] Srom O, Travnikova V, Wutz J, et al. Characterization of hydrodynamic stress in ambr250® bioreactor system and its impact on mammalian cell culture[J]. Biochemical Engineering Journal, 2022, 177.

[6] Zakrzewski R, Lee K, Lye G J. Development of a miniature bioreactor model to study the impact of pH and DOT fluctuations on CHO cell culture performance as a tool to understanding heterogeneity effects at large-scale[J]. Biotechnology Progress, 2022, 38(4).

About Morimatsu LifeSciences

Morimatsu LifeSciences is a key business segment of Morimatsu International Holdings Limited (Stock Code: 2155.HK). It comprises Shanghai Morimatsu Pharmaceutical Equipment Engineering Co., Ltd., Morimatsu (Suzhou) LifeSciences Co., Ltd., Shanghai Morimatsu Biotechnology Co., Ltd., Shanghai Mori-Biounion Technology Co., Ltd., Shanghai Morisora Technology Co., Ltd., Bioengineering AG, Pharmadule Morimatsu AB, and its affiliated companies.

Morimatsu LifeSciences is dedicated in providing core equipment, process systems, and smart modular facility solutions, and services for the pharmaceutical, biopharmaceutical, medical aesthetics, and fast-moving consumer goods (FMCG) sectors including (cosmetics, food, and health supplements), as well as data centers.

Our team comprises highly experienced professionals with deep expertise in process R&D, engineering design, advanced manufacturing, compliance and validation consulting, production execution, and intelligent operations. With broad experience across diverse industries, we fully understand the unique characteristics and process requirements of various products. This enables us to deliver tailored, end-to-end process solutions from the conceptual design stage, precisely aligned with client’s specific needs.

Morimatsu LifeSciences has established a strong global presence, supported by advanced R&D centers, design hubs, and state-of-the-art manufacturing facilities worldwide. Our well-established service network spans Europe,USA,Asia-Pacific, and emerging markets. We have successfully delivered outstanding, customized solutions to clients in over 40 countries and regions, gaining extensive experience in international project execution.

As a multinational enterprise with core strengths in process technology, modular facility construction, and intelligent manufacturing, Morimatsu LifeSciences is dedicated to meeting the evolving equipment and system needs of our key industries. Through continuous innovation and technological advancement, we are steadily expanding our global footprint, driving our international strategy forward, and delivering Morimatsu’s expertise, reliability, and innovation to the global life sciences and related sectors.